A truck driver's average workday is often busy, and time pressure is always a factor. There's also a multitude of things that need to be checked and double-checked – the truck itself, the trailer, and the goods being carried.

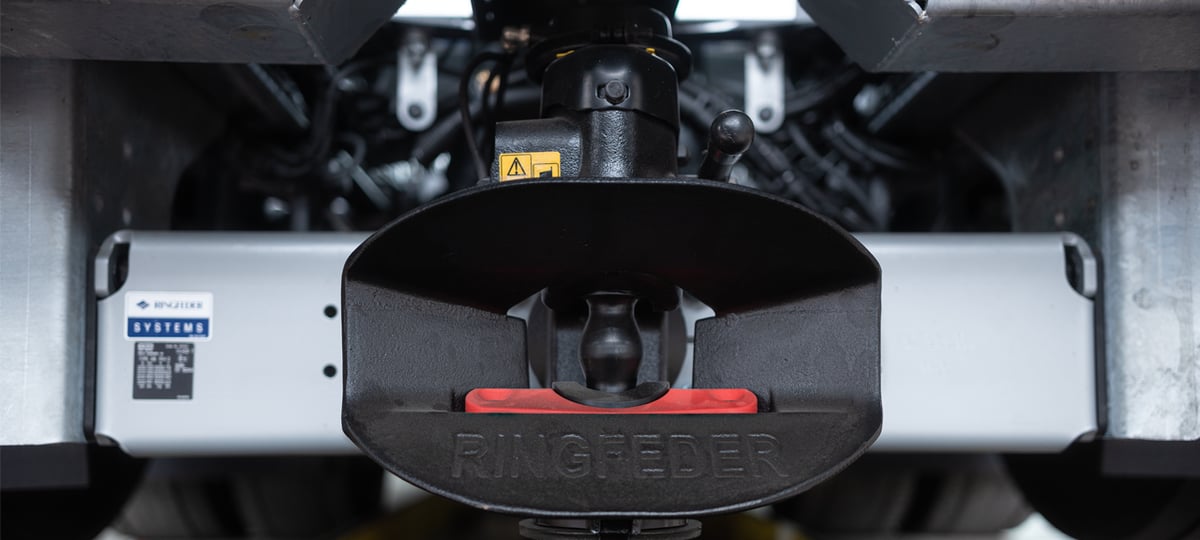

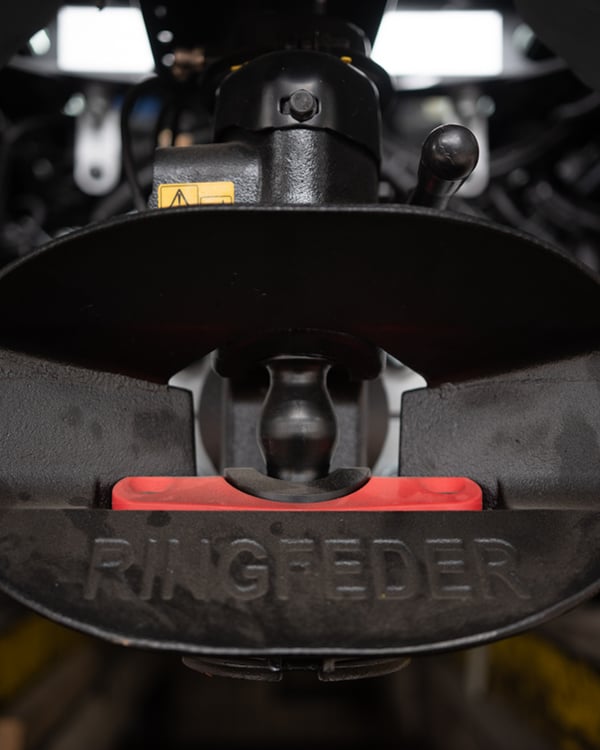

When looking at a fully-loaded vehicle, the coupling appears to be a relatively small part – but as the critical point of contact between a truck and a trailer that is subjected to significant forces during driving, it's one of the most important parts of the whole system. It's certainly not a 'fit-and-forget' component, and getting complacent about coupling maintenance causes serious issues.

Fortunately, the risks of major coupling problems can be significantly reduced with simple checks that drivers can make at the start of every workday. In practice, it can be hard to make this a part of a daily routine – few car drivers check the oil, tire pressure and brakes on their car every time they drive somewhere. However, these checks are essential to lower the chances of frustrating downtime, maintenance, or even serious accidents.

What daily checks should drivers make on their coupling?

To effectively make a standard daily coupling check, the driver should inspect these things at the start of every workday:

- Couple and decouple – This is the simplest way to ensure that the coupling is locking correctly when a trailer is connected and that the coupling can be opened to decouple the trailer when required. When making this test, the driver should keep an eye on the locking indicator to ensure the coupling is fully closed. This is possibly the most crucial check since it provides confidence that the trailer will be securely coupled to the truck when the vehicle gets out on the road. When it is checked at the start of the day, potential problems can be discovered and resolved before they create real issues.

- Check wearing components – Coupling parts such as the wear plate and bolt get worn down with use. A certain amount of wear is acceptable and shouldn't cause any problems, but too much wear can lead to serious issues. Different couplings have different wear thresholds – make sure drivers know what they are and measure them if there is any doubt.

- Make a general visual check for any damage – Even if the coupling mechanism works well and the wear plate looks good, look around the coupling for things like cracks, rust or deformations. These could indicate serious safety problems caused by jackknifing damage or other factors that should be checked out before the coupling is used on the road.

- Stay vigilant when driving – During operation, drivers should keep their eyes open to potential issues. Things like unusual noises, jolts, reduced driving comfort or play between the different components can be another sign of potentially major problems.

- Cleaning and lubrication and other maintenance measures should also happen regularly. Automatic lubrication systems / oil units can do the work for the driver.

And don't forget service intervals – make sure the coupling gets a full service in good time.

Why check trailer couplings daily?

Once again, ensuring these checks become part of the daily routine can sometimes be a challenge. But it's in the best interests of drivers, fleet managers and owners, and even other motorists on the road that they happen at the start of every workday.

Coupling reliability is boosted

By making the checks before a shift starts, you can discover and fix problems early. In other words, it reduces the risks of the driver discovering a major show-stopping problem when they're already at the job site. Staying on top of things like wear to certain components can also make sure that these parts are replaced in good time, rather than at the last minute. The result is a coupling that does its job and provides peace of mind. No one wants downtime, and these checks can help reduce it.

Coupling life is extended (and costs reduced)

A coupling that has been taken care of with simple daily checks and well-timed maintenance has a longer life than one that has simply been mounted and forgotten about. Couplings may not be the most expensive component on a typical goods vehicle, but they come at a cost – and when you consider the cost of removing a truck from service to replace a coupling ahead of its time, the potential savings you can make with daily coupling checks becomes clear.

Truck driver safety is increased

Safety is the most important reason to check trailer couplings on a daily basis. A damaged or heavily worn coupling that is no longer up to the job poses significant risks to truck drivers and other motorists who may get caught up in a potential accident. Checking for damage or functional issues before starting work can save the driver from irritating downtime and potentially save their life.

When problems are discovered, make sure you have a good partner

Simple daily maintenance measures help you feel confident your equipment is up to the task on that day. But when problems are spotted, it's vital to solve them quickly. Your coupling supplier's spare parts and service operation is a deciding factor here. Get in touch to find out more about our approach to meeting your maintenance needs, and subscribe to the blog to get more tips like this sent to your inbox when they become available.