Remote trailer coupling operation and locking indication: What do the regulations say?

Remotely operated couplings and remote locking indicators on trucks and trailers have a significant impact on safety and efficiency.

By being able to operate the coupling and check it is properly locked without going near the coupling itself, the risk of accidents or injury is reduced, and the driver’s daily work is streamlined.

However, as an important piece of safety equipment, the function of remote operation systems and remote locking indicators are regulated – in this case, by the UN’s ECE R55 regulations, or R55 for short. In this article, I will cover the basics of what these regulations involve, and what they mean for your truck or fleet.

What are the benefits of remote coupling operation and indication needed on a truck and trailer?

For the driver, a noticeable daily benefit of remote operation devices is improved ergonomics. If the coupling is mounted low on the truck or trailer or in a hard-to-reach position, remote operation means the driver can open the coupling without having to be right next to it. There are obvious safety benefits as well – remote operation reduces the risk of injuries that can occur when trying to open a stiff opening lever and keeps the operator visible and protected in busy environments.

Once the coupling is operated remotely, a remote indication device can show whether it is closed or open. Remote locking indication may seem like a small feature, but having a clear ‘stop-or-go’ indicator that is clearly visible for the driver and even for pedestrians near the truck at a depot significantly reduces the risks of accidents. Just like remote operation devices, remote locking indicators also help boost ergonomics and efficiency – rather than manually checking a locking indicator on the coupling itself, drivers can simply check their remote indicator on the side of the truck or in their cabin and get going.

Remote operation and indication are not necessary for your coupling and entire operation to work effectively. Many drivers manage simply fine without them, and modern air-assisted couplings take the strain out of opening the coupling manually. However, remote operation and indication devices are small additions that make an enormous difference. To improve safety and ergonomics for the Driver, more and more Fleet Managers implement air-assisted couplings or at least manual couplings with a locking indication by an optical signal, even if it´s not mandatory by the regulation. When the remote locking indication is not required, mostly a sensor with an integrated optical signal (e. g. LED light) is used optionally. By the LED light for example, the Driver can clearly see in front of the coupling, if the coupling is doubly locked. This will make it much easier in the dark and especially if the Drivers is wearing gloves, what could make it difficult to touch and feel the mechanical indicator of the coupling.

What do the ECE R55 regulations say about remote operation and locking indication?

The R55 regulations are 72 pages long and cover everything related to mechanical couplings – so they include a lot of rules not directly related to remote coupling operation and remote locking indication. However, these areas do get some attention. Here are some key regulations that reflect how these devices fit into your daily work or your truck fleet:

- “All the devices for remote indication or remote control fall within the scope of testing and approval of the coupling device together with all parts of the operating devices and transmission devices” – Meaning that the proper function of the remote operation or indication device is a requirement to get type approval. It is not just a nice-to-have feature, it is an important piece of equipment, and the regulations reflect this.

- “The appearance of any fault in the remote indication system shall not indicate a closed and locked position during the coupling procedure if the end position has not been reached” – Meaning you can be sure that even if your indicator is not functioning properly, the device will default to showing an open position. This reduces the risk of the driving setting off with a coupling that is not fully locked.

- “In the event of a failure of the remote control it shall be possible, in an emergency, to open the coupling in at least one other way.” – Meaning a backup opening system, like a handle, must also be in place when a remote operation system is used.

- “If this master switch (to the remote operation device) is not located in the driving cab it shall not be in a position where it is freely accessible to unauthorised persons or it shall be lockable.” – As a key piece of equipment with a major safety role, making sure unauthorized users cannot operate the coupling is essential.

In addition, the regulations specify that remote operation devices must be used in these situations:

- When it is not easy and safe to operate the coupling manually – for example, if the coupling's position on the truck of the vehicle design creates a risk of injury or entrapment if the operator must open the coupling manually.

- When the coupling is not easily accessible (defined as 550mm between the centre of the coupling pin and the edge of the vehicle bodywork, 650mm for vehicles with tipping bodies or rear-mounted equipment, 1320mm if there is at least 1150mm of unobstructed height between the coupling and the ground, or in the case of car transporters with at least two levels where the trailer is not normally separated from the truck in normal operation).

- When there is only a small area of clearance around the hand lever.

Like many of the ECE regulations, rules like these are updated and changed over time. An update in 2016, for example, made it possible for remote indicators to be mounted on the side of the vehicle, rather than just in the cab.

And a more recent update from 2022 removed the previous rule that remote operation and indication devices could only be used on C50-X and G50-X-class couplings.

What solutions are available for coupling operation and indication?

Indication

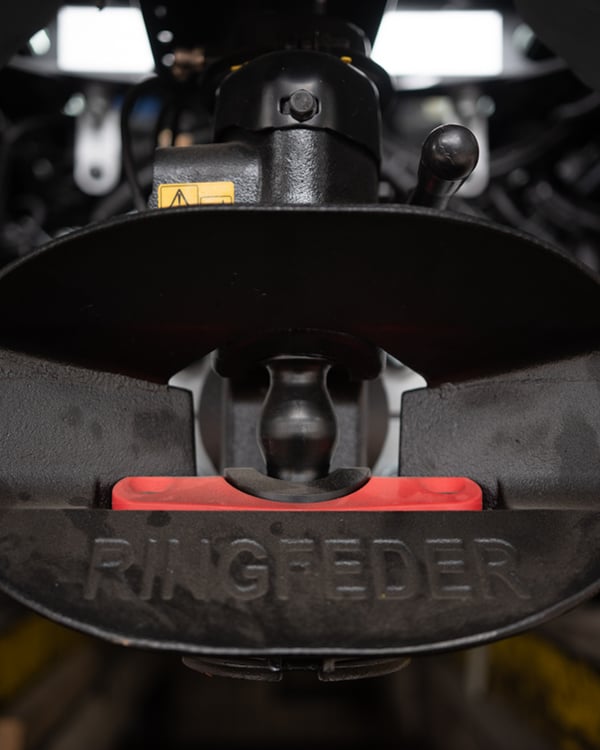

According to R55, if a remote operation device is used, remote indication must also be in place. Depending on the use case, the indicator can be mounted on the side of the vehicle or in the cab, in the driver’s field of vision. These cab indicators can be integrated into the truck’s built-in display or elsewhere on the instrument panel. The R55 regulations even cover the colours that must be used – green when the coupling is fully closed and locked, and red when it is not.

Operation

These two operation methods are commonly used:

- Manual – These couplings are opened with a manually-operated lever mounted on the coupling itself. The operator must go to the coupling and lift the lever to move the coupling to the open position. It is a simple and time-proven solution but is not always convenient (or permitted) if the coupling is hard to reach.

- Air Mechanism (AM) – This is an air-assisted opening solution for remote operation. With AM-powered couplings, the driver gets some help to open the bolt from the truck’s existing air system. When it is time to decouple, the driver connects the air hose to the coupling, returns to the cabin, and uses their normal air controls to open the coupling with a blast of air, rather than manually opening it with the handle. This takes the strain out of opening the coupling and can be the only way to raise the bolt if the coupling is mounted in a difficult position.

A third operating method is a Mechanism for an air assisted opening and closing of the coupling.

Just like everything related to truck and trailer couplings, there is plenty of regulations and trade-offs to consider when choosing and installing the best system for you. The best approach is to think about the needs of the driver. Their safety is vital, and anything that can make their work less strenuous and time-consuming improves their day and gets your operation moving quicker.

To find out more about the range of remote operation and indication options available, get in touch – we will be happy to guide you to a solution that benefits both your drivers and your bottom line.