Underrun protection is a critical component of a truck and trailer– from a safety perspective as well as a regulatory and economic one. Although it seems like a relatively simple component, your choice of underrun protection can significantly complicate the process of designing, building and operating goods vehicles.

In this article, let’s go through the basics around underrun protection and look at how underrun protection affects you, depending on the kind of role you have.

Types of underrun protection

Underrun protection devices all have the same simple purpose – improving safety for other road users by preventing them from getting lodged under a truck or a trailer in the event of an accident. Originally, they were known as ‘Mansfield bars’, named after actress Jayne Mansfield who was killed in an accident in 1967 when her car collided with a rear end of a vehicle and slid underneath the trailer. It’s exactly this kind of accident that underrun protection devices are designed to prevent.

Rear underrun protection devices (also known as RUPDs) protect against underrunning in rear-end collisions, while side underrun protection devices (SUPDs) provide protection in side-on crashes, as well as for cyclists or pedestrians who risk ending up under the vehicle in an urban environment. In this article, we’ll take a deeper look at RUPDs and explain what you should think about when choosing them.

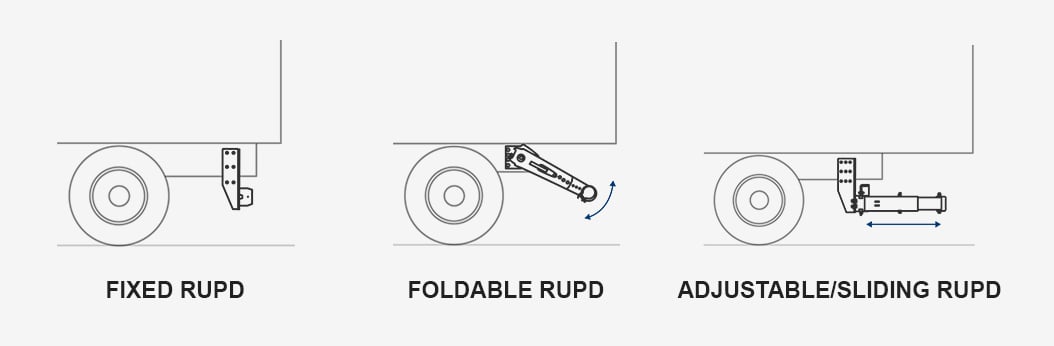

Even if all RUPDs have the same purpose, they can work differently depending on the truck build and the operator's needs. There are three main kinds of RUPDs:

- Fixed RUPD – This is simply a fixed underrun protection beam mounted on the truck or the trailer chassis using a bracket. Removable beams that can be lifted on and off can be used with fixed RUPDs, but this is as adjustable as things get with this type of system.

- Foldable RUPD – This flexible system is mainly designed for trucks where the coupling is mounted below the truck in a deep underslung position. When a trailer must be coupled, the underrun protection bar can be folded up to make room for the drawbar, but it must be folded down once the trailers are uncoupled to provide protection.

- Adjustable or sliding RUPD – This specialised solution is for example used in container applications, on hook lifts and on tipper trucks, among other situations. Adjustable underrun protection devices can slide inwards horizontally. To give an example, when a tipper truck tips its bed to deposit its load, the underrun protection beam can slide inwards to make room for the tipping bed. And when a container needs to be removed from a roll-off truck, the RUPD can slide inwards to make room.

Why is underrun protection important?

For most professionals that work with trucks in their daily work, underrun protection usually poses three main challenges – regulations, truck and trailer construction, and cost (particularly the total cost of ownership). Let's look at each one in more detail.

You need to comply with laws and regulations around underrun protection

Like many other components, the type of underrun protection devices you mount on your trucks or trailers are governed by international regulations. In 2019, the transport industry had to deal with the third revision to the R58 regulations, which led to the sharpening of requirements in these areas:

- Stricter and fairer test setup and demands

- Shorter maximum rear overhang and lower minimum ground clearance

- Heavier structural dimensions

As truck traffic levels increase and safety demands become even stricter, regulations may change again – creating a new regulatory environment that the industry must live with. For example, 2024 will see updates to the EU's General Safety Regulations (GSR), which will require all new trucks to be fitted with a range of safety devices such as reversing sensors, tyre pressure monitors and blind spot devices. The new GSR won't place any further demands on underrun protection, but they're a good example of the increasingly firm regulations that businesses in the transport industry face.

Failing to meet these regulations doesn't just put other road users at risk – they can also lead to fines and other severe consequences for businesses. So, staying on top of the rules and regulations that affect you and sourcing your underrun protection devices from a knowledgeable, serious supplier with the correct certifications is the best way to avoid unpleasant surprises in the future and make the type approval process easier.

Your choice of RUPD affects the rest of the vehicle

For a vehicle manufacturer involved in planning and designing a new truck or trailer system, the underrun protection device significantly impacts the vehicle as a whole. Weight is a significant factor, especially since the third revision to the R58 regulation raised the minimum forces RUPDs must withstand. A steel RUPD capable of stopping a speeding car will always have a heavy, robust construction, and in some cases, the extra weight it adds means that weight savings need to be made elsewhere. Additionally, a heavy RUPD or a poorly designed folding mechanism can create issues for the driver and put ergonomics at risk. Lightweight RUPDs made from lighter metals like aluminium are an alternative for some applications.

Legal requirements also affect RUPD dimensions, ground clearance and overhang. In some cases, this can mean that your desired construction isn't possible – so underrun protection deserves a great deal of attention early on in the planning stage if you want things to go to plan later on.

Your underrun protection system impacts your costs

From a cost perspective, underrun protection devices have an effect. For example, complicated mounting routines for your RUPDs make construction more time-consuming and costly. Additionally, the introduction of the third revision to the R58 regulation resulted in a much smaller pool of suppliers capable of delivering RUPDs that met the new certification requirements. This situation now is different from 2019, but it illustrates how a seemingly simple component like an underrun protection device can have a significant effect.

With all these challenges in mind, it’s smart to look for reputable suppliers that offer system solutions covering couplings, underrun protection, drawbeams, end plates and accessories in one package. The temptation to shop around for the lowest possible purchase price can be strong, but in the long run, system solutions spare you the headaches that come with this approach and lead to the lowest total cost of ownership.

Keep learning more about underrun protection and our range of RUPDs by taking a look at our products, or get in touch with us if you need a solution to your challenges around underrun protection.